PRODUCTS

Electronicmagnetic Water Descaling Equipment

Key words:Water Filter、UV Sterilizer、Ion Exchange Water softener

product description

The descaling device is one of the new technologies in the water industry. In the 1980s, it was widely used in cooling circulation, heat exchangers, hot water boilers and other water systems in industrialized countries. Our company has made breakthrough progress while digesting and absorbing domestic and foreign technologies. It is estimated that compared with the chemical method, it can save equipment investment by 60%~70%, save water by 80%, improve efficiency by more than 18%, and save 1300KW of electricity per ton of water, while the operating cost only accounts for 1/350. Only saving electricity and water can recover all the investment in that year. More superior is no pollution, long service life, can be used continuously for more than 15 years, one investment, many years of benefit.

working principle

※Scaling and anti-scaling

Combining the research and experience of a number of technologies, a new generation of multi-functional high-frequency descaling device has been successfully developed. It uses modern electronic technology and molecular surface energy rearrangement technology, so that after the water body absorbs high-frequency electromagnetic energy, it does not change the original composition. Under the circumstance, its physical structure changes, the original associative chain macromolecule is broken into a single water molecule, the positive and negative ions of the dissolved salt in the water are surrounded by a single water molecule, the movement speed is reduced, the number of effective collisions is reduced, and the electrostatic attraction is reduced. Calcium and magnesium ions in water cannot be combined with carbonate ions to form calcium carbonate and magnesium carbonate, thereby achieving the effect of anti-scaling. At the same time, because the water body absorbs a large number of excited electrons, the dipole moment of the water body increases, and the affinity with the positive and negative ions of the salt increases, so that the original scale on the pipe wall gradually becomes soft and even falls off, achieving an effective descaling effect. .

※Bactericidal and algae killing

Due to the turbulence created by high-frequency electromagnetic waves in the water body, the ion channels of the cell membrane are destroyed. Changes the internal control current of cell adaptation and the environmental conditions required for survival, causing it to lose its viability and die. At the same time, the stimulated water molecules can surround and block the dissolved oxygen in the water, cutting off the source of oxygen required for microorganisms to carry out life reactions, thereby achieving a better sterilization and algae killing effect and preventing the production of biological sludge.

※ Anti-rust and anti-corrosion

When the water body receives the action of high-frequency electromagnetic energy, a single water molecule contains the oxygen molecules dissolved in the water, making the dissolved oxygen into inert oxygen, and cutting off the source of oxygen required for metal corrosion. At the same time, the "skin effect" generated by the electromagnetic field of the pendant compound modulation frequency excited by high-frequency electromagnetic waves accumulates excess negative charges on the tube wall, while excess positive charges accumulate inside the water, and the excess positive charges in the water strongly repel the band. Positively charged Fe3﹢ prevents Fe from losing electrons to become Fe3﹢, separates from the metal wall and enters the water (yellow rust water produced in the system is the color of Fe3﹢ in water). At the same time, the excess negative electrons on the tube wall also continuously attract Fe3 with positrons to prevent Fe3 from dissolving into the water, so that the original Fe2O3 (red rust) on the tube wall can be reduced to black rust with strong corrosion resistance. Membrane Fe3O4.

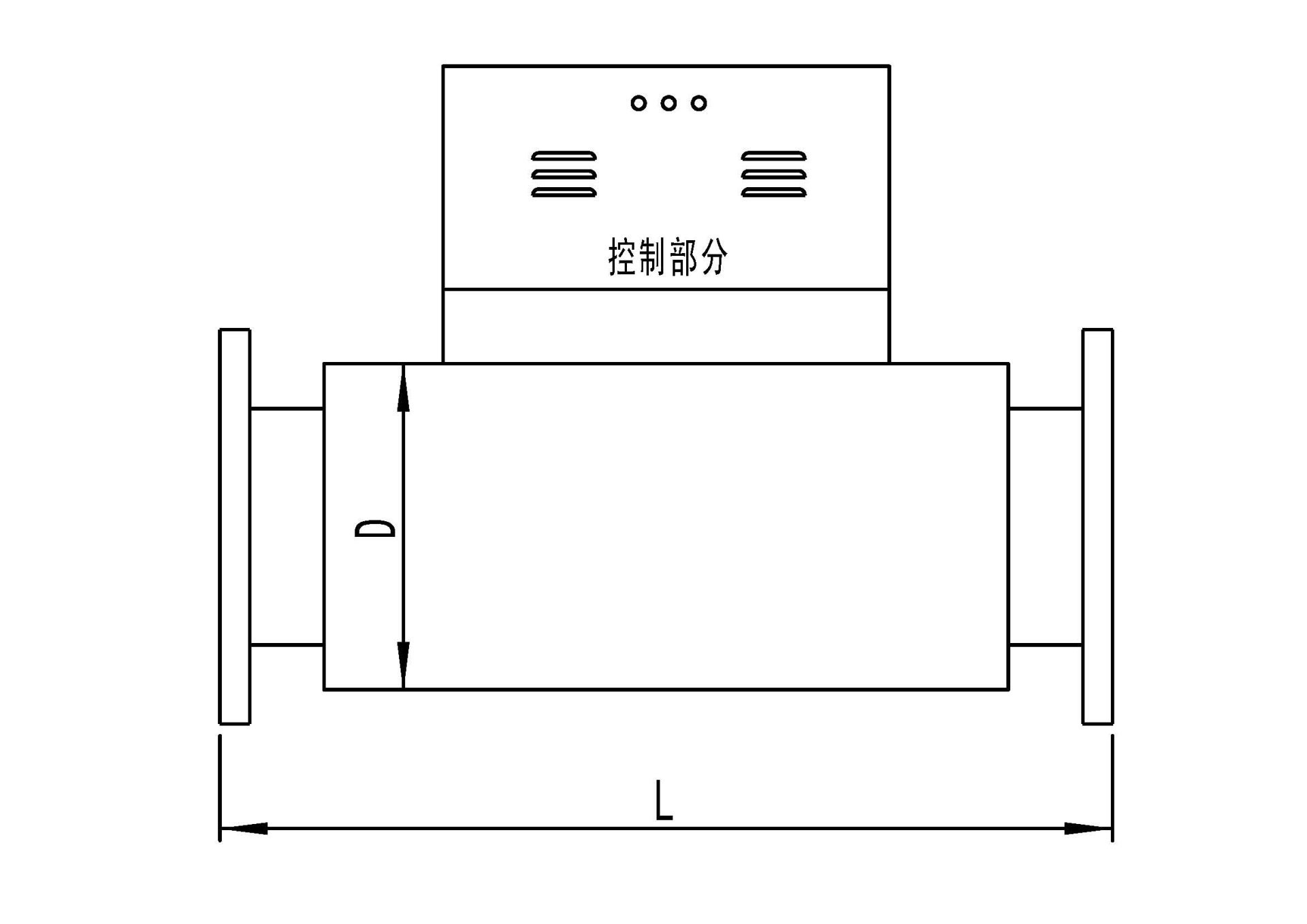

Selection reference table

| model |

flow (T/h) |

Exit and entry diameter |

D (mm) |

L (mm) |

input power (W) |

net weight (Kg) |

|

|

mm |

in |

||||||

|

YL-0.5 |

1.8 |

15 |

0.5 |

159 |

500 |

25 |

35 |

|

YL-1 |

4.9 |

25 |

1 |

159 |

500 |

25 |

35 |

|

YL-1.5 |

12 |

40 |

1.5 |

159 |

500 |

25 |

35 |

|

YL-2 |

19 |

50 |

2 |

159 |

500 |

25 |

35 |

|

YL-2.5 |

28 |

65 |

2.5 |

159 |

500 |

25 |

40 |

|

YL-3 |

50 |

80 |

3 |

219 |

600 |

50 |

45 |

|

YL-4 |

80 |

100 |

4 |

219 |

600 |

50 |

50 |

|

YL-5 |

125 |

125 |

5 |

219 |

600 |

70 |

55 |

|

YL-6 |

180 |

150 |

6 |

273 |

600 |

70 |

65 |

|

YL-8 |

320 |

200 |

8 |

325 |

700 |

80 |

80 |

|

YL-10 |

490 |

250 |

10 |

377 |

700 |

120 |

90 |

|

YL-12 |

710 |

300 |

12 |

426 |

750 |

210 |

120 |

|

YL-14 |

1000 |

350 |

14 |

478 |

800 |

250 |

130 |

|

YL-16 |

1400 |

400 |

16 |

530 |

850 |

330 |

150 |

|

YL-18 |

1600 |

450 |

18 |

630 |

900 |

410 |

180 |

|

YL-20 |

1970 |

500 |

20 |

720 |

950 |

500 |

200 |

|

YL-24 |

2850 |

600 |

24 |

820 |

1000 |

660 |

260 |

|

YL-28 |

3880 |

700 |

28 |

920 |

1100 |

900 |

320 |

The above data is for reference only, and the data of each product shipped shall prevail.

product advantages:

1. Less investment, low operating cost, only limited electricity fee

2. Small size, small footprint, easy installation

3. No noise, no odor, no need to add any chemical ingredients

4. Maintenance-free 15-year design service life

5. Personnel-free operation and fully automatic processing

6. Solid-state silicon circuit design, stable and reliable work

7. Anti-scaling, descaling, sterilization and algae killing, anti-rust and anti-corrosion, activate water quality

Selection Notes:

1. Under normal circumstances, the diameter of the water pipe of the equipment should be consistent with the inlet and outlet of the descaling device. If the designed pipe diameter is increased, the water processor must also be consistent with it.

2. In the following cases, it is recommended that the user choose a model with a larger one. pass:

The water flow speed of the water processor is greater than 2.8 m/s

The total water hardness is greater than 700mg/L (calculated as CaCo3)

Water temperature ≤ 100℃

3. The general design pressure of the water processor is 1.0MPa. If the pressure exceeds this standard, please specify it when ordering.

Technical indicators:

※ Input power: 220V-50Hz.

※ Adapt to water quality: total hardness ≤ 1000mg/L (calculated as CaCo3) water temperature ≤ 100 ℃ flow velocity ≤ 2.8 m/s

※ Anti-scaling rate: high

※ Scale removal rate: high

※ Corrosion resistance: The corrosion rate of the pipeline is reduced to 1/10 of the original

※ Design life: 15 years for the main engine, 20 years for the auxiliary engine

※ Sterilization rate: high

※ Algae eradication rate: high

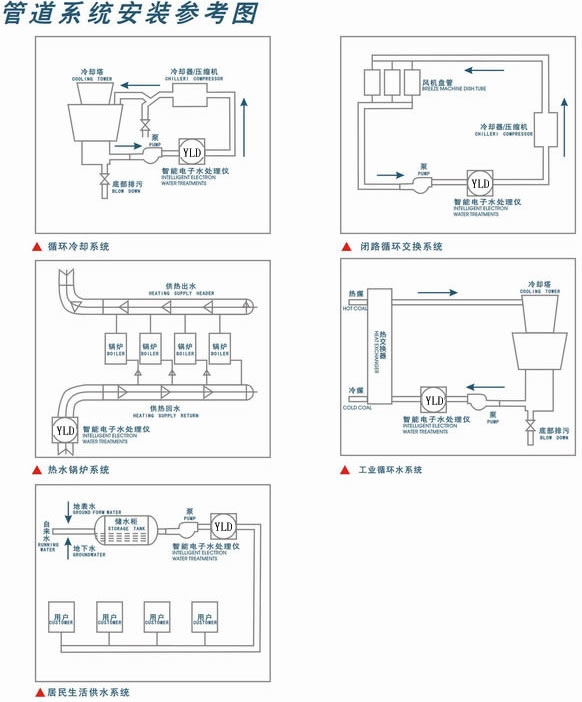

Installation and precautions:

1. Determine the specifications of the water treatment instrument according to the flow, pressure and pipe diameter;

2. The water treatment instrument should be connected in series in the pipeline, close to the main equipment (such as condensers, heat exchangers, cooling towers, etc.); the water entering the heating part in the circulation system must flow through the water treatment instrument, that is, the water treatment instrument should Installed on the circulation line. This equipment should be installed at the outlet pipe of the pump, and try to avoid installation at the suction pipe;

3. New equipment and systems can be directly installed with water treatment instruments. For systems with severe scaling (scaling thickness ≥ 2.5mm), the scale must be removed before installing the water treatment instrument to prevent the scale from falling off and clogging the pipeline;

4. For the circulating water system that operates all the year round, a bypass pipeline should be set up so that the water treatment instrument can be repaired without stopping;

5. The electronic water treatment instrument should be installed indoors. If it must be installed outdoors, a rainproof device should be installed; during the installation and handling process, do not subject the electronic controller to force or moisture;

6. Above the electric controller or along the opening direction of the electric controller, an unobstructed space of no less than 600mm should be reserved for maintenance;

7. This product should be used with caution on steam or tube frame boilers.

Related Products

*Note: Please fill in the information accurately and keep the communication unblocked. We will contact you as soon as possible