PRODUCTS

Constant Pressure Water Supply And Vacuum Degassing

Key words:Water Filter、UV Sterilizer、Ion Exchange Water softener

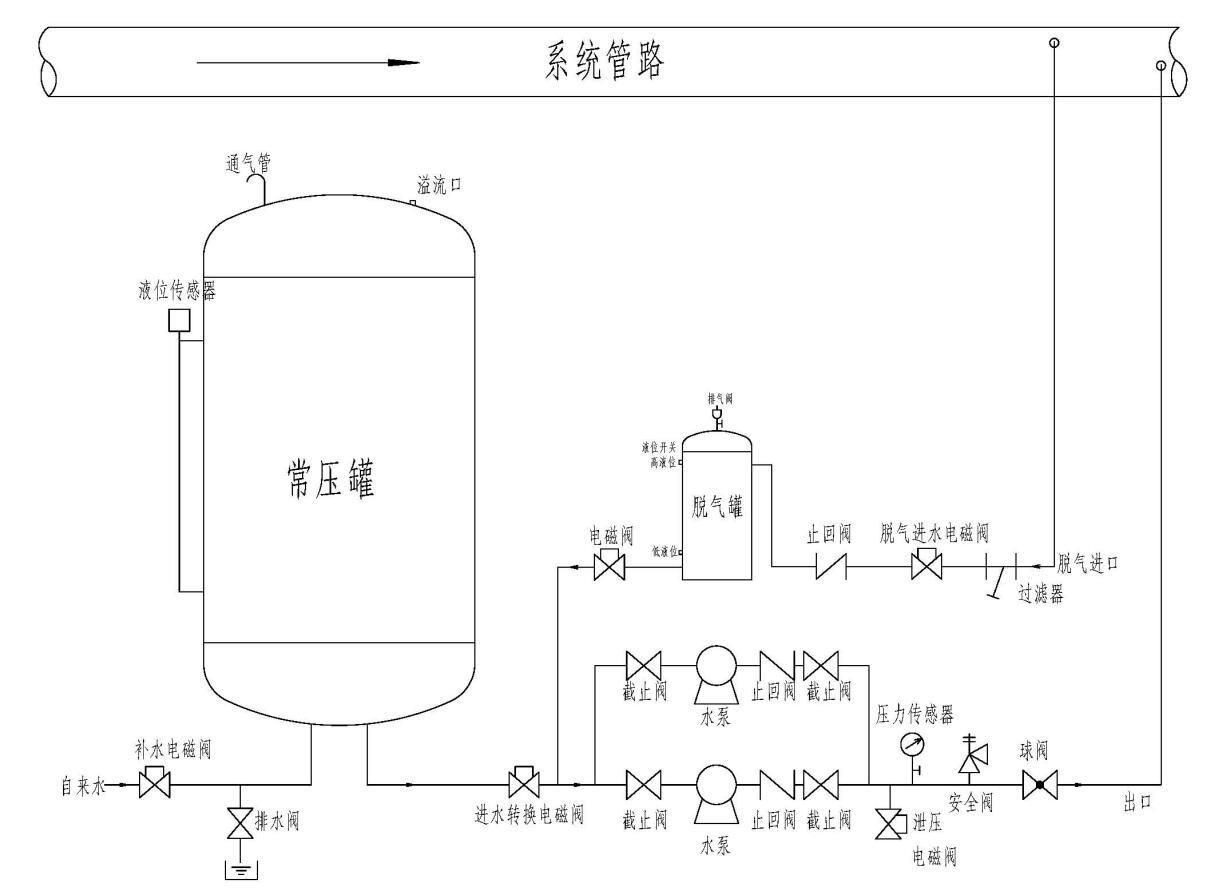

Atmospheric pressure tank product introduction and principle

Constant pressure replenishment vacuum degassing unit is based on the physical principle, through the vacuum tank and atmospheric diaphragm tank, the free bubbles and dissolved gas in the water are separated, so that the gas is completely separated from the water, which can ensure the solution of the air in the system. The problem is that there is no gas even at the highest point of the system and any possible corners, and the pressure of the system can be stabilized. The high-precision constant pressure and timely water replenishment ensure the efficient operation of the circulating water system.

Constant pressure replenishment vacuum degassing unit consists of control system, replenishment pump, atmospheric diaphragm tank and vacuum degassing tank, which are widely used in heating, cooling, glycol and solar energy systems.

Atmospheric pressure tank type function

Constant pressure: when the medium is heated, the volume will expand due to the increase in temperature, and the entire system will be under pressure

The pressure rises, when the pressure rises to the opening pressure of the pressure relief solenoid valve, the pressure relief in the equipment

The solenoid valve opens, and the medium in the system that expands in volume due to heating is discharged to the atmospheric tank

, keep the system pressure constant.

Water replenishment function: When the hot water is dissipated by the cooling equipment, the temperature drops and the volume decreases, and the system pressure drops,

When the pressure drops to the starting pressure of the make-up pump, the water pump will transfer the water stored in the atmospheric tank or

Other peripheral water supply sources are supplied to the system through the make-up pump to maintain a constant system pressure.

Vacuum deoxygenation: the water added to the system or the water exported from the system can be degassed in a vacuum state,

Exhaust dissolved gas, free gas, large air bubbles, etc. in the system to protect equipment and systems

The system runs safely and stably.

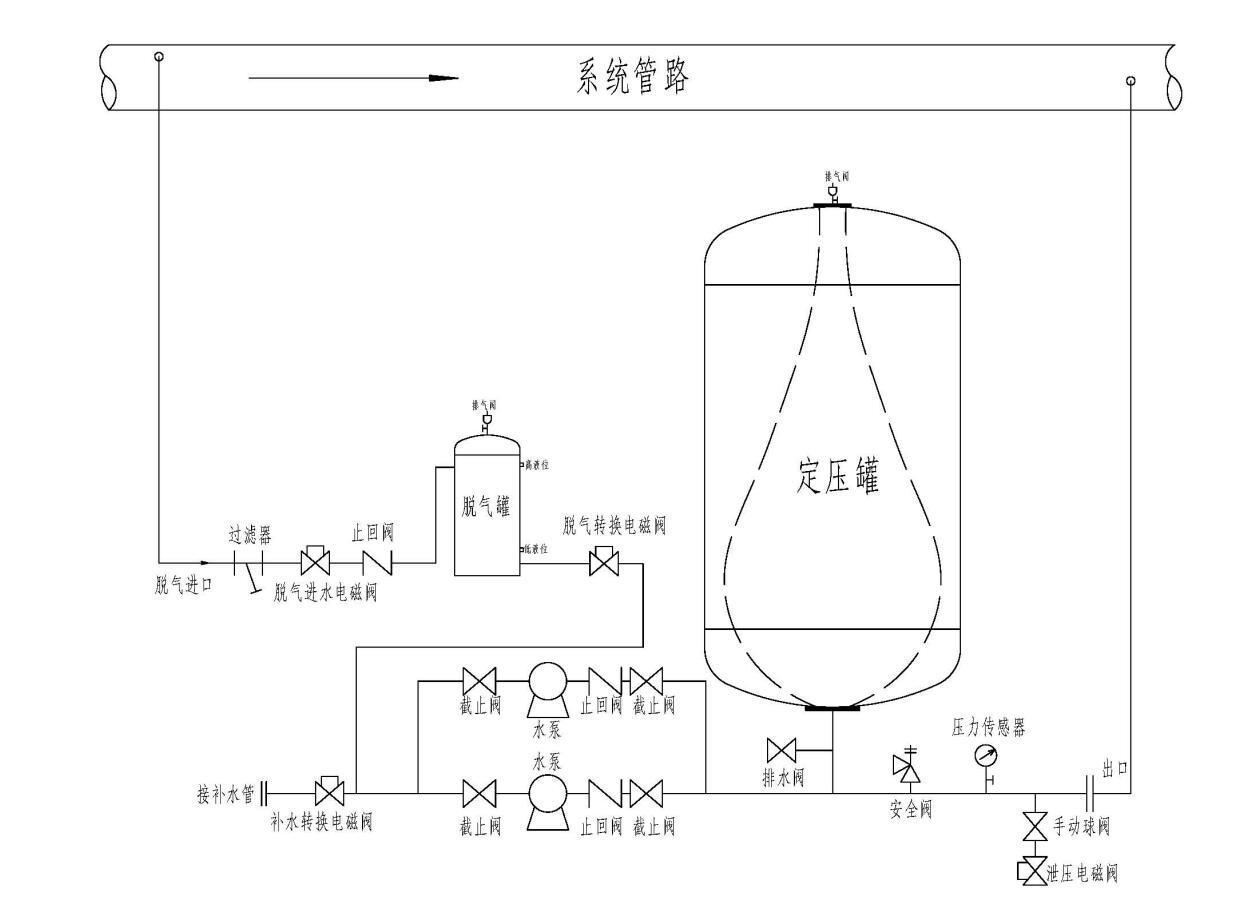

Introduction and principle of constant pressure tank type products

The biggest difference of the constant pressure tank of the constant pressure replenishment vacuum degassing unit is that the constant pressure tank replaces the atmospheric pressure tank, and all the exhaust functions are completed by the vacuum degasser. The vacuum degasser and constant pressure tank are used together to minimize the instability caused by system fluctuations, and to a large extent solve the phenomenon of live connection or valve burst caused by sudden pressure increase in the system. High-precision constant pressure, efficient exhaust, the combination of soft and hard improves the stability of the system.

Technical parameters

Power supply voltage: 220V/380V, 50HZ

Operating pressure: ≥0.1MPa

Allowable working temperature: 0~70℃

Allowable ambient temperature: 0~70℃

Free gas removal capacity: 100%

Protection level: IP55

Maximum allowable pressure: 1.6MPa

Allowable instantaneous temperature: 0~120℃

Dissolved gas removal capacity: ≥90%

Technical Features

1. Diaphragm capsules are installed in the tank to prevent water from contacting the tank wall to prevent pollution;

2. Small footprint, low investment, quick installation, easy operation management and maintenance;

3. Eliminate the high water tank in the building and save the structural investment;

4. The water tank acts as a buffer, which can eliminate the impact of water hammer on the pipe network;

5. Automatic control and reliable operation;

6. Regulate the expansion and contraction of the water body due to temperature fluctuations;

7. Vacuum degassing eliminates the phenomenon of air resistance, air hammer and "red water" in the circulation system, and improves the working efficiency of the system.

8. Effectively remove the air in the system, and the removal rate reaches 90%, which effectively prevents the chemical oxidation and corrosion of the inner wall of the equipment in the system, greatly prolongs the service life of the equipment and pipes, and improves the heat transfer efficiency of the equipment.

Related Products

*Note: Please fill in the information accurately and keep the communication unblocked. We will contact you as soon as possible