PRODUCTS

Double Valve Double Tank Water Softener- small flow

Gategory:

Key words:Water Filter、UV Sterilizer、Ion Exchange Water softener

Since the introduction of the automatic water softener more than ten years ago, Yilida has been focusing on the development and promotion of softening water equipment in line with China's national conditions. Yilida series water softener, which is composed of JK type, JM type, FLECK type and JB type water softener, draws on the advantages of many domestic and foreign companies, and provides users with different application scopes with their own reasonable and practical series of softening water equipment.

Selection Tips

| Raw water hardness | ≤8mmol/L | Power | 220V/50HZ |

| Water hardness | ≤0.03mmol/L | Control method | Traffic, Time |

| Inlet pressure | 0.25~0.5Mpa | Resin | 001×7 Strong acid cation exchange resin |

| Free chlorine | ≤0.3mg/L | Working ambient temperature | 5-50℃ |

| Suspended solids | <0.5mg/L | System water temperature | 2-50℃ |

| Iron Content | <0.3mg/L | Relative Humidity | ≤95%(25℃) |

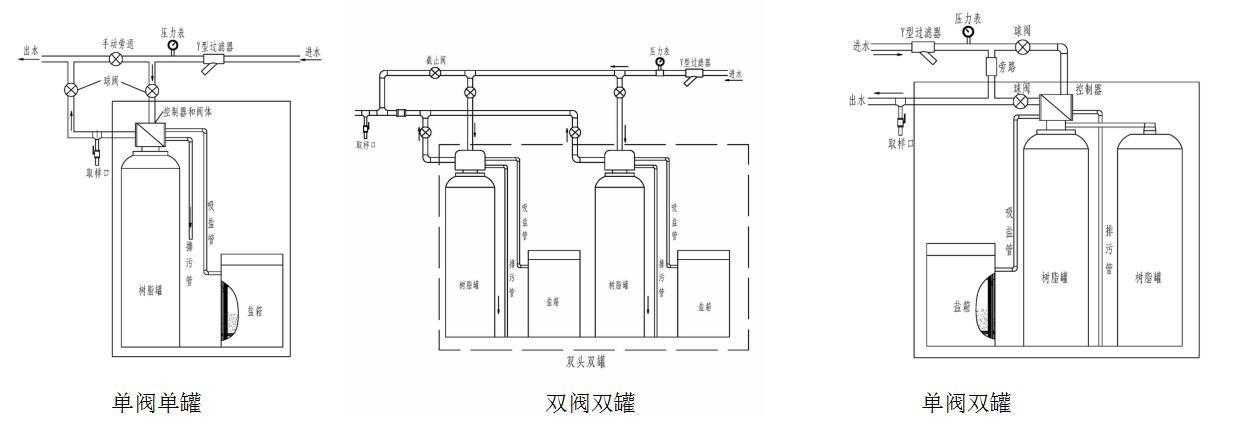

Installation diagram

Selection reference table

| Category | Model | Recommended water yield | Tank Dimensions Diameter & times; Height (mm) |

Salt Box (L) |

Amount of resin (Kg) |

| Single valve single tank | YL-I-0.5 | 0.5 | 200×900 | 60 | 20 |

| YL-I-1 | 1 | 250×1400 | 60 | 40 | |

| YL-I-2 | 2 | 300×1400 | 100 | 60 | |

| YL-I-3 | 3 | 350×1400 | 130 | 80 | |

| YL-I-4 | 4 | 400×1650 | 200 | 120 | |

| YL-I-5 | 5 | 500×1750 | 300 | 180 | |

| YL-I-6 | 6 | 600×1900 | 350 | 240 | |

| YL-I-10 | 10 | 750×1900 | 500 | 360 | |

| YL-I-18 | 18 | 900×1900 | 800 | 520 | |

| YL-I-25 | 25 | 1000×2200 | 1000 | 720 | |

| YL-I-35 | 35 | 1200×2400 | 1500 | 1000 | |

| YL-I-50 | 50 | 1500×2500 | 2000 | 1600 | |

| Double valve double tank (run simultaneously, regenerate separately) |

YL-II-36 | 36 | 900×1900 | 800 | 1040 |

| YL-II-50 | 50 | 1000×2200 | 1000 | 1440 | |

| YL-II-70 | 70 | 1200×2400 | 1500 | 2000 | |

| YL-II-100 | 100 | 1500×2500 | 2000 | 3200 | |

| Double valve double tank (one for use and one for backup) |

YL-II-1 | 1 | 250×1400 | 60 | 80 |

| YL-II-2 | 2 | 300×1400 | 100 | 120 | |

| YL-II-3 | 3 | 350×1400 | 130 | 160 | |

| YL-II-4 | 4 | 400×1650 | 200 | 240 | |

| YL-II-5 | 5 | 500×1750 | 300 | 360 | |

| YL-II-6 | 6 | 600×1900 | 350 | 480 | |

| YL-II-10 | 10 | 750×1900 | 500 | 720 | |

| YL-II-18 | 18 | 900×1900 | 800 | 1040 | |

| YL-II-25 | 25 | 1000×2200 | 1000 | 1440 | |

| YL-II-35 | 35 | 1200×2400 | 1500 | 2000 | |

| YL-II-50 | 50 | 1500×2500 | 2000 | 3200 | |

| JK type hydraulic drive Single valve double tank |

JK25-150 | 0.2-0.3 | 200×900 | 25 | 40 |

| JK30-200 | 0.5-0.6 | 200×1200 | 60 | 40 | |

| JK60-250 | 0.8-1.0 | 250×1400 | 60 | 80 | |

| JK100-300 | 1.8-2.0 | 300×1400 | 100 | 120 | |

| JK200-350 | 2.8-3.0 | 350×1650 | 100 | 160 | |

| JK200-400 | 3.5-4.0 | 400×1650 | 200 | 240 |

The above data is for reference only, and the data of each shipment shall prevail.

Control method

(1) Single-tank time type: using microcomputer time control, the equipment will automatically enter the regeneration state after running to the set time, and it can be regenerated once a day or for multiple days

Regenerate once.

(2) Single-tank flow type: using turbine flow control or electronic flow sensor control, when the water produced by the equipment reaches the preset flow, it will automatically enter the regeneration state

Status, which can regenerate multiple times per day.

(3) Double-tank flow type: It can be divided into one-use and one-standby type and simultaneous operation and separate regeneration type.

One use and one backup type: one tank is running and the other is standby. When the water from the first running tank reaches the set flow, it enters the regeneration stage, and at the same time the other one

The tank enters the working state, so that the two tanks work alternately for regeneration, and can supply water continuously for 24 hours.

Separate regeneration type for simultaneous operation: two tanks operate at the same time, after reaching the flow rate, one will regenerate first and the other will continue to discharge water, and the first regeneration will be completed after regeneration

Enter the working state, the other enters the regeneration state, and the two tanks enter the simultaneous working state after the regeneration is completed.

Related Products

*Note: Please fill in the information accurately and keep the communication unblocked. We will contact you as soon as possible