PRODUCTS

Air Separator Water Filter

Gategory:

Key words:Water Filter、UV Sterilizer、Ion Exchange Water softener

Product introduction

YSG series self-cleaning exhaust water filter is a multi-functional system component with automatic differential pressure alarm, gas-water separation and filtration functions. The self-cleaning ability of the filter is strong, and the filter screen does not need to be cleaned frequently. Effectively remove impurities such as iron oxide scale, old scale, sludge and air in the water system to ensure the cleanliness of the water quality. This product is widely used in industrial cooling water system, air conditioning water system, heat exchange water system, production and domestic hot water supply system, hot water heating boiler water system, etc.

How it works

The air in the water system is prone to corrosion and damage to the water pump, boiler, heat exchanger, refrigerator and other equipment and components in the system, resulting in a reduction in the service life and efficiency of the system. Only setting the exhaust valve at the high point of the system is not effective. When the pressure is reduced, the gas dissolved in the water will re-form bubbles, especially before the pump, a large amount of gas will be separated.

The self-cleaning exhaust water filter utilizes the mechanisms of gas-water separation, sedimentation, filtration, etc. When the water in the cooling water, hot water, and chilled water system enters the self-cleaning exhaust water filter, the volume expands and rapidly increases. Sharply reduced, the water bubbles separate and rise to the gas-gathering area, and the small bubbles are adsorbed on the gas-water separation device. When large bubbles are formed and rise to the gas-gathering area, they are discharged through the automatic exhaust valve. In the circulating water with dirt, the dirt settles with the water flow in the filter. After passing through the gas-water separation device, the dirt is accelerated and quickly settles in the dirt storage area on both sides of the filter element. Due to the large dirt capacity of the dirt storage area, Just open the drain valve regularly. After air and dirt are separated, clean water flows into the pump inlet through the filter element. Due to the vibration of the filter element under the impact of the pump and the water flow, the residues attached to the outside of the filter element fall off, realizing self-cleaning.

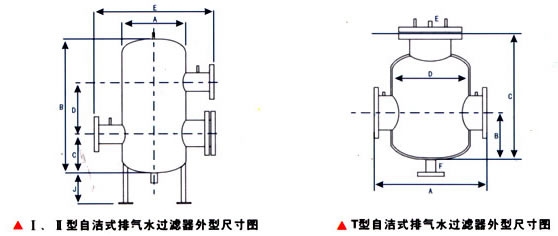

YSG-Ⅰ, Ⅱ self-cleaning exhaust water filter reference data

| Specifications | Import and export dimensions | A mm |

B mm |

C mm |

D mm |

E mm |

J mm |

Flow T/h |

Weight Kg |

|

| mm | in | |||||||||

| YSG-3 | 80 | 3 | 325 | 700 | 220 | 260 | 645 | 180 | 18-45 | 108 |

| YSG-4 | 100 | 4 | 377 | 785 | 245 | 300 | 698 | 180 | 45-70 | 140 |

| YSG-5 | 125 | 5 | 426 | 880 | 265 | 350 | 750 | 200 | 60-110 | 175 |

| YSG-6 | 150 | 6 | 500 | 1030 | 315 | 410 | 825 | 200 | 70-158 | 220 |

| YSG-8 | 200 | 8 | 600 | 1240 | 385 | 480 | 925 | 250 | 158-280 | 275 |

| YSG-10 | 250 | 10 | 700 | 1420 | 435 | 560 | 1025 | 250 | 280-440 | 360 |

| YSG-12 | 300 | 12 | 800 | 1610 | 485 | 650 | 1125 | 280 | 440-640 | 495 |

| YSG-14 | 350 | 14 | 900 | 1840 | 540 | 750 | 1225 | 280 | 640-865 | 695 |

| YSG-16 | 400 | 16 | 1000 | 2070 | 595 | 850 | 1425 | 300 | 865-1130 | 760 |

| YSG-18 | 450 | 18 | 1100 | 2295 | 660 | 960 | 1525 | 300 | 1130-1430 | 945 |

| YSG-20 | 500 | 20 | 1200 | 2400 | 740 | 1080 | 1625 | 320 | 1430-1800 | 1235 |

| YSG-24 | 600 | 24 | 1300 | 2600 | 840 | 1200 | 1825 | 320 | 1800-3000 | 1460 |

YSG-T self-cleaning exhaust water filter reference data

| Specifications | Import and export dimensions | A mm |

B mm |

C mm |

D mm |

E mm |

F mm |

Flow T/h |

Weight Kg |

|

| mm | in | |||||||||

| YSG-3 | 80 | 3 | 460 | 175 | 450 | 273 | 15 | 40 | 15-20 | 62 |

| YSG-4 | 100 | 4 | 520 | 210 | 540 | 325 | 15 | 40 | 25-35 | 85 |

| YSG-5 | 125 | 5 | 580 | 235 | 620 | 377 | 15 | 40 | 45-60 | 114 |

| YSG-6 | 150 | 6 | 640 | 260 | 700 | 426 | 15 | 40 | 60-85 | 165 |

| YSG-8 | 200 | 8 | 720 | 300 | 800 | 500 | 15 | 50 | 90-130 | 230 |

| YSG-10 | 250 | 10 | 780 | 360 | 1000 | 500 | 15 | 50 | 150-260 | 300 |

| YSG-12 | 300 | 12 | 890 | 440 | 1250 | 600 | 15 | 50 | 250-400 | 360 |

| YSG-14 | 350 | 14 | 1000 | 460 | 1350 | 700 | 15 | 50 | 450-650 | 440 |

| YSG-16 | 400 | 16 | 1120 | 515 | 1500 | 800 | 15 | 50 | 650-900 | 510 |

| YSG-18 | 450 | 18 | 1180 | 560 | 1600 | 900 | 15 | 65 | 900-1100 | 580 |

| YSG-20 | 500 | 20 | 1300 | 620 | 1800 | 1000 | 15 | 65 | 1150-1500 | 660 |

| YSG-24 | 600 | 24 | 1400 | 690 | 2100 | 1100 | 15 | 80 | 1600-2000 | 740 |

Installation and precautions

1. During installation, the direction of water flow should be consistent with the direction indicated by the equipment;

2. Set up a bypass pipeline as much as possible so that the normal operation of the system will not be affected when the filter is cleaned or fails;

3. When the filter is used together with the water treatment equipment, it should be installed before the water inlet of the water treatment equipment.

Main technical parameters

1. Pressure range: 0.6, 1.0, 1.6Mpa

2. Applicable temperature≤95℃

3. Exhaust rate: high

4. Pollution rate: high

5. Special specifications can be customized according to user requirements

6. Flange connection size is according to GB/T9119-2000

Filter accuracy comparison table

| microns | 200 | 300 | 400 | 500 | 600 | 700 | 640 | 260 | 700 | 426 | 15 | 40 | 60-85 | 165 |

| YSG-8 | 200 | 8 | 720 | 300 | 800 | 500 | 15 | 50 | 90-130 | 230 | ||||

| YSG-10 | 250 | 10 | 780 | 360 | 1000 | 500 | 15 | 50 | 150-260 | 300 | ||||

| YSG-12 | 300 | 12 | 890 | 440 | 1250 | 600 | 15 | 50 | 250-400 | 360 | ||||

| YSG-14 | 350 | 14 | 1000 | 460 | 1350 | 700 | 15 | 50 | 450-650 | 440 | ||||

| YSG-16 | 400 | 16 | 1120 | 515 | 1500 | 800 | 15 | 50 | 650-900 | 510 | ||||

| YSG-18 | 450 | 18 | 1180 | 560 | 1600 | 900 | 15 | 65 | 900-1100 | 580 | ||||

| YSG-20 | 500 | 20 | 1300 | 620 | 1800 | 1000 | 15 | 65 | 1150-1500 | 660 | ||||

| YSG-24 | 600 | 24 | 1400 | 690 | 2100 | 1100 | 15 | 80 | 1600-2000 | 740 |

Installation and precautions

1. During installation, the direction of water flow should be consistent with the direction indicated by the equipment;

2. Set up a bypass pipeline as much as possible so that the normal operation of the system will not be affected when the filter is cleaned or fails;

3. When the filter is used together with the water treatment equipment, it should be installed before the water inlet of the water treatment equipment.

Main technical parameters

1. Pressure range: 0.6, 1.0, 1.6Mpa

2. Applicable temperature≤95℃

3. Exhaust rate: high

4. Pollution rate: high

5. Special specifications can be customized according to user requirements

6. Flange connection size is according to GB/T9119-2000

Filter accuracy comparison table

| microns | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 | 1600 | 2000 |

| mm | 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 0.9 | 1 | 1.6 | 2 |

| Mesh | 80 | 60 | 45 | 32 | 28 | 24 | 22 | 20 | 18 | 12 | 10 |

Pipeline system installation reference diagram

Related Products

*Note: Please fill in the information accurately and keep the communication unblocked. We will contact you as soon as possible