PRODUCTS

Circulating water bypass filtration system

Gategory:

Key words:Water Filter、UV Sterilizer、Ion Exchange Water softener

Product introduction and principle

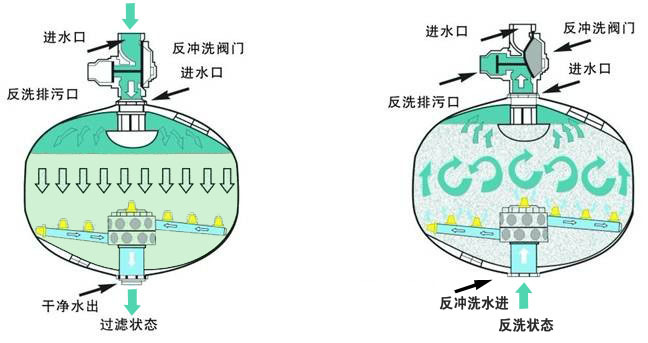

The high-speed shallow sand tank filter, also known as the circulating water bypass filter, adopts the bypass filter, instead of installing the filter on the general circulation pipeline to filter all the circulating water, it is led out on the general circulation pipeline. Part of the circulating water is filtered, which is to filter the impurities in the system through the step-by-step cycle interception, and finally remove the impurities from the system through the necessary backflushing. By installing a high-speed shallow sand tank filter on the circulating water system, it is possible to prevent sludge clogging in the end pipelines in the system, and cooperate with dosing treatment to effectively remove impurities in the system and reduce the turbidity of the circulating water system. It is said that it is to reduce the slime, avoid its deposition in the heat exchanger, and better play the role of the agent.

The high-speed shallow sand tank filter adopts a modular design, which can be flexibly selected according to different flow rates and land occupations.

Selection reference table

| model |

flow (T/h) |

diameter (mm) |

high (mm) |

Exit and entry diameter (mm) |

filter area (m2) |

|

YLD-SF-800 |

15-25 |

800 |

960 |

50 |

0.50 |

|

YLD-SF-1000 |

23-39 |

1000 |

1200 |

50 |

0.79 |

|

YLD-SF-1200 |

33-55 |

1200 |

1400 |

80 |

1.13 |

|

YLD-SF-1400 |

45-75 |

1400 |

1600 |

100 |

1.54 |

|

YLD-SF-1600 |

60-100 |

1600 |

1800 |

100 |

2.01 |

|

YLD-SF-1800 |

75-125 |

1800 |

1950 |

150 |

2.54 |

|

YLD-SF-2000 |

95-155 |

2000 |

2150 |

150 |

3.14 |

|

YLD-SF-2200 |

115-190 |

2200 |

2250 |

150 |

3.80 |

|

YLD-SF-2400 |

130-210 |

2400 |

2300 |

150 |

4.52 |

|

YLD-SF-2600 |

145-225 |

2600 |

2400 |

150 |

5.30 |

|

YLD-SF-2800 |

155-240 |

2800 |

2500 |

200 |

6.15 |

|

YLD-SF-3000 |

170-255 |

3000 |

2600 |

200 |

7.00 |

以上數據僅供參考,以每次出貨産(chǎn)品數據為(wèi)準。

Technical Description

The design of the bypass filtration flow is based on 5%~10% of the total circulation volume, and the filtration rate can be designed according to the water quality of the system at 20~35m/h. For the corrosive suspended matter and control of the circulating water system, our technicians have designed a variety of manual/automatic bypass filtration equipment that meets the needs of customers.

Design Features

1. High filtration speed and low pressure loss, completely solve the problems of slow filtration speed and small flow of ordinary mechanical media filters;

2. Modular setting, small footprint, less piping, and low investment. Easy to install, just connect the water inlet and outlet and the sewage pipe;

3. It can be controlled manually or automatically, and automatic and time, differential pressure and other methods can be used;

4. The backwash water source can be selected from the system, water tower or external water source, and can be automatically switched (when special requirements). High backwash efficiency, backwash time

Short, less water consumption for backwashing, the water consumption is about 30% of the traditional sand filter;

5. The internal water distributor is evenly and reliably arranged, and the finishing water collector has high strength and long service life.

Related Products

*Note: Please fill in the information accurately and keep the communication unblocked. We will contact you as soon as possible