PRODUCTS

Manual Brush Filter

Key words:Water Filter、UV Sterilizer、Ion Exchange Water softener

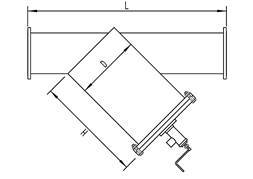

Hand brush filter

The internal structure of the hand-cranked brush filter is composed of stainless steel wire brushes and stainless steel filter screen rotating parts. The cleaning device is installed on the inner side of the stainless steel filter screen, and the filter cover is equipped with a handle. Shake the handle to drive the cleaning part to brush off the particles on the filter screen, and then discharge it through the sewage outlet. The water flow is not interrupted during the brushing process, and there is no need to stop and remove the filter to clean the filter screen.

Technical parameter

※Working pressure: ≤1.0MPa (over this pressure, please specify when ordering)

※Pressure loss: ≤0.015MPa

※Working temperature: ≤150℃

※Filter precision: d=1.2mm

Others: The filtration precision and size can be customized according to user requirements, and the flange connection size is according to GB-9119.8-88.

Y-type hand brush filter selection reference table

| model |

flow (T/h) |

Exit and entry diameter |

Sewage diameter (mm) |

D (mm) |

L (mm) |

H (mm) |

weight (kg) |

|

|

mm |

in |

|||||||

|

YL-2Y |

19 |

50 |

2 |

25 |

159 |

550 |

300 |

70 |

|

YL-2.5Y |

28 |

65 |

2.5 |

25 |

159 |

550 |

300 |

73 |

|

YL-3Y |

50 |

80 |

3 |

25 |

159 |

600 |

300 |

75 |

|

YL-4Y |

80 |

100 |

4 |

25 |

159 |

600 |

300 |

80 |

|

YL-5Y |

125 |

125 |

5 |

25 |

219 |

600 |

350 |

90 |

|

YL-6Y |

180 |

150 |

6 |

32 |

275 |

650 |

350 |

100 |

|

YL-8Y |

320 |

200 |

8 |

40 |

325 |

850 |

525 |

120 |

|

YL-10Y |

490 |

250 |

10 |

50 |

377 |

900 |

650 |

150 |

|

YL-12Y |

710 |

300 |

12 |

50 |

426 |

1000 |

700 |

260 |

|

YL-14Y |

970 |

350 |

14 |

65 |

478 |

1100 |

820 |

350 |

以上數據僅供參考,以每次出貨産(chǎn)品數據為(wèi)準。

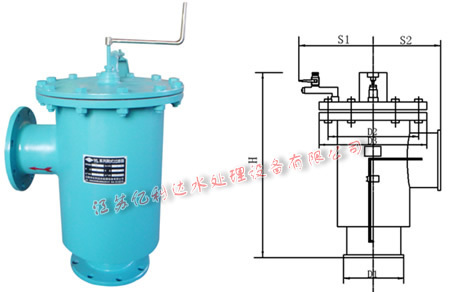

Vertical hand-cranked brush filter

Selection parameter table

| model | Import and export parameters | Outlet parameters |

H |

S1 |

S2 |

flow(T/h) |

weight |

|||

|

mm |

in |

D1 |

D2 |

D3 |

||||||

|

YL-2L |

50 |

2 |

Φ150 |

Φ240 |

Φ285 |

517 |

300 |

225 |

19 |

80 |

|

YL-2.5L |

65 |

2.5 |

Φ150 |

Φ240 |

Φ285 |

517 |

300 |

225 |

28 |

100 |

|

YL-3L |

80 |

3 |

Φ150 |

Φ240 |

Φ285 |

537 |

300 |

225 |

50 |

130 |

|

YL-4L |

100 |

4 |

Φ207 |

Φ295 |

Φ340 |

587 |

300 |

225 |

80 |

150 |

|

YL-5L |

125 |

5 |

Φ260 |

Φ350 |

Φ395 |

630 |

300 |

285 |

125 |

180 |

|

YL-6L |

150 |

6 |

Φ309 |

Φ400 |

Φ445 |

641 |

300 |

311 |

180 |

230 |

|

YL-8L |

200 |

8 |

Φ367 |

Φ460 |

Φ505 |

823 |

398 |

340 |

320 |

280 |

|

YL-10L |

250 |

10 |

Φ406 |

Φ515 |

Φ565 |

975 |

423 |

365 |

490 |

320 |

|

YL-12L |

300 |

12 |

Φ406 |

Φ515 |

Φ565 |

1000 |

438 |

365 |

710 |

380 |

|

YL-14L |

350 |

14 |

Φ460 |

Φ565 |

Φ615 |

1068 |

463 |

395 |

970 |

450 |

以上數據僅供參考,以每次出貨産(chǎn)品數據為(wèi)準。

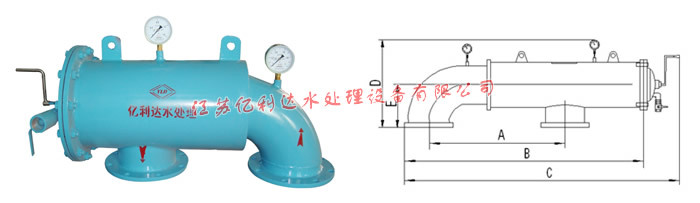

F type hand brush filter

Selection parameter table

| model |

A |

B |

C |

D |

E |

|

YLSF2 |

460 |

1190 |

1750 |

465 |

228 |

|

YLSF4 |

460 |

1210 |

1770 |

465 |

228 |

|

YLSF6 |

620 |

1740 |

2800 |

470 |

235 |

|

YLSF8 |

800 |

1840 |

2900 |

545 |

308 |

Selection method

1. Determine the following parameters: working flow or inlet and outlet pipe diameter DN, working pressure P, working temperature, filtration accuracy.

2. Determine the structural form according to the site installation location.

3. Determine the relevant materials: filter material, shell material.

4. Determine the filter model.

installation and use

The hand-cranked brush filter can be installed horizontally or vertically, but it should be noted that the direction of water flow should be consistent with the direction of the arrow on the casing. When it is vertical, the direction of water flow is required to be from top to bottom. When the pressure difference between the inlet and outlet reaches 0.04MPa, the blowdown valve needs to be opened, and the handle is gently turned manually to brush the filter screen. After the water quality of the blowdown outlet becomes clear, the brushing and blowdown are stopped. The whole blowdown process system can operate normally without downtime.

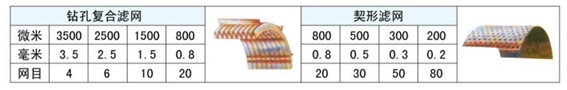

Standard filter level

Related Products

*Note: Please fill in the information accurately and keep the communication unblocked. We will contact you as soon as possible