PRODUCTS

Ultrafiltration device

Gategory:

Key words:Water Filter、UV Sterilizer、Ion Exchange Water softener

1.1 Overview and principle of ultrafiltration membrane

Ultrafiltration technology is a nano-scale membrane separation technology. The hollow fiber ultrafiltration process uses the hollow fiber membrane as the filter medium, and the pressure difference between the inside and outside of the membrane as the driving force. The process of separating substances of the size of the diameter to achieve the purpose of purifying, separating, purifying and concentrating the solution.

The pore size of ultrafiltration membranes is approximately in the 0.002-0.1 micron range (MWCO is approximately 1,000-500,000). Dissolved substances and substances smaller than the pore size of the membrane can pass through the filter membrane as permeate, and the substances that cannot pass through the filter membrane will be intercepted and concentrated in the discharge liquid. Therefore the produced water (permeate) will contain water, ions and small molecular substances, while colloidal substances, particles, bacteria, viruses and protozoa will be removed by the membrane.

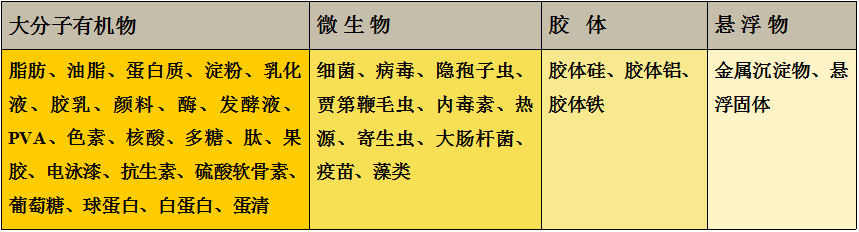

1.2 Substances that can be retained by ultrafiltration

1.3 Fields of Ultrafiltration Applications

| Pretreatment of raw water (seawater, surface water, groundwater, tap water) | Reverse osmosis pretreatment clarifier instead of sand filtration instead of ion exchange EDI pretreatment or posttreatment Rural townships treat surface water and well water for drinking < /td> |

| Production process water treatment (removal of bacteria, pollution, particles and suspended solids) | Drinking water Medical water Electronic grade pure water Food and beverage water Reverse osmosis pretreatment Industrial water |

| Purification | Remove particles (such as 18 megohm water), remove microorganisms and pyrogens, cooperate with RO or ion exchange treatment (such as power plant boiler make-up water) |

| Water recycling and reuse (recycled water or wastewater from industrial water) | Reuse of circulating water, cooling water, condensate water, re-injection water, and collected water in petroleum, chemical, steel mills, and power plants; municipal sewage and wastewater treatment and reuse; Food processing; textile; printing and dyeing; papermaking; printing; electroplating; chemicals; metal raw materials; transportation; leather; latex; cosmetics; electronic industry and other industries. |

| Material concentration and purification | Food fermentation, concentration in dairy industry; alcohol sterilization, turbidity removal, clarification, etc. |

1.4 Advantages of ultrafiltration system in groundwater treatment

1.4.1 Stable filtration effect: ultrafiltration filtration has reached nano-level filtration, and the quality of the product water is little affected by the quality of the raw water, which can ensure the stability and consistency of the quality of the product water.

1.4.2 Low energy consumption: normal temperature and pressure operation, low energy consumption;

1.4.3 High Efficiency: High utilization rate of raw liquid and little waste.

1.4.4 Small footprint: ultrafiltration equipment is compact and can be installed in layers.

1.4.5 Wide filtration range: Ultrafiltration membranes can be made into products with different filtration precisions of 0.002μm~0.1μm for different applications.

1.4.6 There is no phase change in the whole process: ultrafiltration separation is a pure physical separation at room temperature. It does not require high temperature, and there is no chemical action. After ultrafiltration, the properties of the substance will not change, and neither There are secondary residues.

1.4.7 It is convenient to expand the capacity. When the processing capacity needs to be expanded, it is only necessary to increase the membrane host module of the corresponding processing capacity.

System process description

System Description

This ultrafiltration system is used as a terminal treatment to further remove turbidity, organic matter, microorganisms and other indicators. The system consists of 1 set of ultrafiltration equipment and supporting equipment. The ultrafiltration equipment includes 24 AQU200-PVC-W-100KH (UPVC) membrane components. Produced water ***T/H.

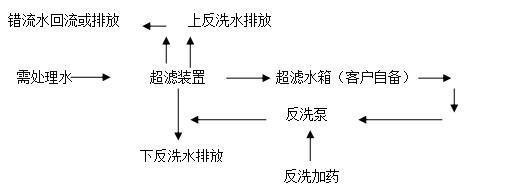

Brief description of process flow

Before the water to be treated in this system enters through the pump, it should be ensured that the influent water meets the influent conditions of the membrane modules in this system.

2.3.1 Ultrafiltration feed water pump

The system needs to be equipped with 1 feed pump. The start and stop of the pump corresponds to the ultrafiltration equipment. It is used to transport the water source to be filtered, overcome the extended range resistance and provide power for the UF system to ensure the pressure requirements of the system.

2.3.2 Ultrafiltration device

Ultrafiltration membrane is a pure physical process of separating, purifying, purifying and concentrating substances in feed liquid by using nano-scale physical pore size under certain pressure. Ultrafiltration component is the core part of ultrafiltration system , its function removes impurities such as suspended solids, colloids, chromaticity, turbidity, organic matter, bacteria and Escherichia coli. Ultrafiltration has the characteristics of small footprint, stable and consistent effluent quality, and high degree of automation. The system adopts AQUCELL's AQU200-PVC-W-100KH (UPVC) ultrafiltration membrane, the module is hollow fiber type, and the membrane material is modified composite polyvinyl chloride material, which is hydrophilic, chemically stable, mechanically High strength and toughness.

Ultrafiltration is external pressure filtration during operation. The system adopts PLC control, automatic backwashing, and continuous operation.

Membrane element features:

1. The wall thickness of the end cover is thickened and the reinforced rib explosion-proof design is adopted, and the pressure bearing capacity exceeds 1.6MPa;

2. Backwash with water from the central pipe, the dispersion radius of the water flow is the shortest, and the water distribution holes in the central pipe are evenly distributed;

3. The membrane wire is divided into independent sectors by the spacer. The spacer is combined with the central tube. The spacer in the membrane allows the ultrafiltration membrane backwash cloth water to be drained evenly to each sector, and the backwash pressure of the membrane wire in the cavity Balanced, the backwash effect is better;

4. The center pipe joint and the end cover adopt a double-sealing structure, which can effectively prevent water leakage at the connection between the center pipe and the end cover;

5, 304 stainless steel clamp structure, the components have stronger pressure bearing capacity, effectively preventing burst and water leakage caused by instantaneous high pressure and impact in medium and large ultrafiltration systems;

6. The connector adopts the national standard size quick-release ferrule, which is quick, simple and reliable to install;

7. The end cap and the cylinder are bonded with glue imported from the United States, with extremely high bonding strength, ensuring no water leakage and no degumming;

8. The end sleeve casting layer adopts an anti-degumming design structure, so that the epoxy resin and the end sleeve are nested with each other to form a complete whole to ensure the adhesion and sealing between the epoxy resin and the end sleeve;

p>

9. End sealing material: epoxy resin with high hardness, high strength, high toughness and high hygiene.

2.3.3 Backwash system

After the ultrafiltration runs for a certain period of time, a small amount of dirt will accumulate on the surface of the membrane. In order to maintain the flux of the membrane element and the dirt does not adhere quickly, regular gas-liquid backwashing is used to remove the pollutants on the membrane surface. Backwashing adopts ultrafiltration product water, excellent water quality can ensure the effect of backwashing, and will not damage the membrane module. The backwash system includes a backwash pump and a backwash dosing system.

2.3.3.1 Backwashing water pump: The system is equipped with a backwashing pump, which is used to transport backwashing water and provide sufficient backwashing pressure to ensure the backwashing effect.

2.3.3.2 Dosing system: In order to ensure the effect of backwashing, the system is equipped with a set of oxidant dosing system. During backwashing, the oxidant can kill and peel off the microorganisms attached to the membrane surface, and at the same time oxidize and decompose the refractory macromolecules that foul the membrane, and restore the flux of the membrane.

Dosing box: one for preparing and storing oxidant solution;

Dosing pump: one.

2.3.4 Chemical cleaning system

After long-term operation of the ultrafiltration system, some difficult-to-wash dirt will accumulate, such as organic matter, inorganic salt scaling, etc., and the film-forming performance will decrease. Such dirt must be cleaned with chemicals to remove.

2.3.4.1 Chemical cleaning pump: The system is equipped with a UF cleaning pump shared with the original water pump; it is used to provide the flow and pressure required for chemical cleaning.

2.3.4.2 Cleaning water tank: used to prepare chemical cleaning agents.

2.3.4.3 Chemical cleaning filter: used to prevent contaminants from entering the membrane surface during chemical circulation.

2.3.5 Control Instruments

In order to control and monitor the normal operation of the ultrafiltration system.

Related Products

*Note: Please fill in the information accurately and keep the communication unblocked. We will contact you as soon as possible